Description

Compliant with the legislation in force

The Input – Output system is an integrated control system for the operation of gas stations, which controls and records all fuel movements and station transactions.

The software has been created by ELBIS from scratch, and offers full control over sales, fuel stock, daily revenue and all the necessary, according to the current legislation, information. It can be connected and control all the stations’ peripherals, it can print receipts, be connected to a tax mechanism and send data to the ministry, as defined by law.

The operation of the Inputs – Outputs system is fully harmonized with the requirements and specifications of the legislation, as determined by GG 137/07-08-2009, the Ministerial Decisions I2-1617/07-12-2010 and I2-2022/ 14-11-2012, the Clarifying CN 1009/04-01-2012 & CN 1203/26-11-2012 and the instructions issued by the Ministry of Transport and the Metrology Directorate of the Ministry of Development.

It consists of:

- A measurement subsystem for fuel level and temperature in the tanks.

- Fuel output monitoring subsystem from the electronic pumps.

- Central unit (console) for controlling and processing data of the subsystems.

- Program for updating and sending data to public authorities (GSIS).

It offers:

- Continuous fuel level-volume measurement inside each tank.

- Monitoring – recording of all pump movements.

- Comparison with the corresponding tank changes.

- Intake Subsystem – Fuel Receipt and Leak Detection.

- Collection and assurance of measurement data.

- Generation of bulletins, sending on a tracking database.

- Linking to an appropriate type of approved tax mechanism.

System capabilities

The system monitors any fuel change in the tanks at natural temperature and open at 15°C (such as fuel pickup, tank outflow due to pump fuel sale, tank leakage) and pump outflows based on the current temperature of the connected tank. Compares the differences upon reception between the tank monitoring system and the receipt document, at natural temperature and after cooling to 15°C and the outflow differences at natural temperature and opened at 15°C between tanks and pumps, based on system measurements or receipt documents. The details of the shipping document upon receipt are entered into the system, in order to be comparable with the system readings in the tanks and with those of the pump outflows.

Input – Output System Equipment

The software of the Input – Output System is entirely made by ELBIS and controls the inflows and outflows of pumps and tanks of the gas station.

It gives users full control over sales, fuel stock, daily revenue and all the necessary, according to the current legislation, information. It can be connected and control all the stations’ peripherals, it can print receipts, be connected to a tax mechanism and send data to the ministry, as defined by law.

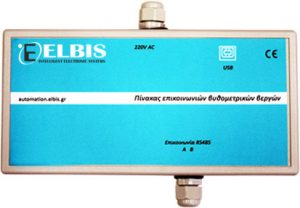

Communication device linking the I/O system console with the electronic pumps that have an RS485 communication protocol. It is programmed exclusively for each type of pump.

Communication device linking the I/O system console with the electronic pumps that have an RS422 communication protocol. It is programmed exclusively for each type of pump and has eight (8) communication channels (communicates with 8 CPUs) of the same type. It is powered by a cable, from the computer’s USB port.

Communication device linking the I/O system console with the electronic pumps that have an RS422 communication protocol. It is programmed exclusively for each type of pump and has eight (8) communication channels (communicates with 8 CPUs) of the same type. It is powered by a cable, from the computer’s USB port.

Communication device linking the I/O system console with the electronic pumps that have an RS422 communication protocol. It is programmed exclusively for each type of pump and has eight (8) communication channels (communicates with 8 CPUs) of the same type. It is powered by a cable, from the computer’s USB port.

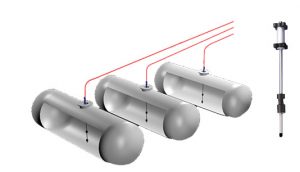

For our system we use high precision dipsticks, fully certified according to ATEX, CE, ISO 9001:2000 and OIML R85. It is possible to order a specific height and cross-section dipstick depending on the depth of the tank. By using the dipsticks we ensure the uninterrupted level measurement of the fuel volume inside each tank, the collection of measurement data, the correct receipt of the fuel from the fuel truck and the detection of possible leaks in the fuel tanks.

The console software is connected to peripheral equipment, which is necessary to issue the necessary documents required by law.

- Approved tax mechanism for marking unverified tax documents with triple interface (Ethernet, USB, Serial).

- Thermal printer connectable to the tax mechanism, automatically printing sales receipts.

- A4 Laser printer used to print the data of the I/O system (balance sheets, receipts slips, export slips, etc.)